Project Scope:

Loader drivers were accidentally hitting a steel wall whilst backing up to unload due to a very dusty operating environment, contributing to impaired driver vision. A lighting solution was required to better penetrate the dust, improve operator visibility and reduce the number of vehicle to wall collisions.

Loader drivers were accidentally hitting a steel wall whilst backing up to unload due to a very dusty operating environment, contributing to impaired driver vision. A lighting solution was required to better penetrate the dust, improve operator visibility and reduce the number of vehicle to wall collisions.

Proposed Solution:

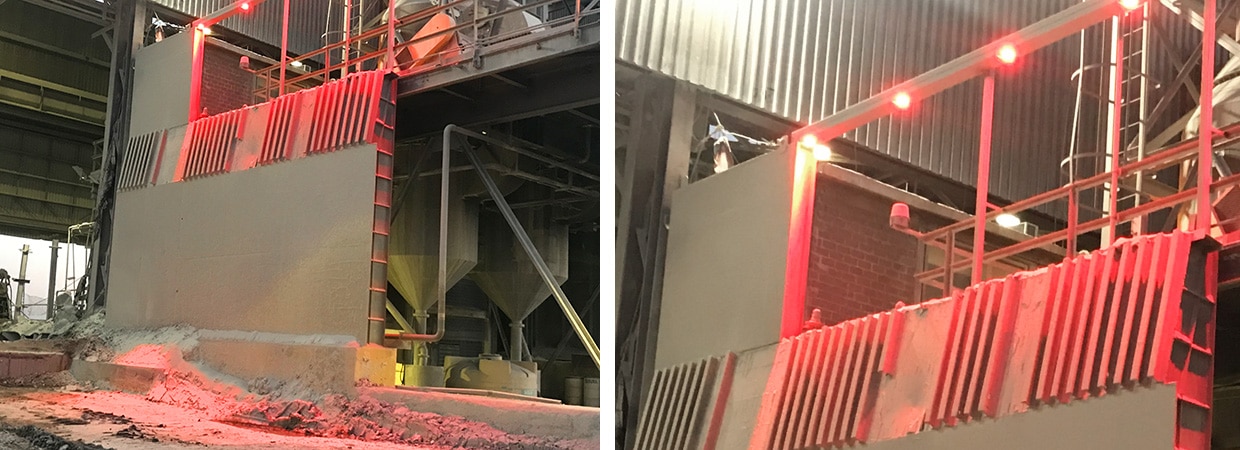

Instead of mounting the Red Zone lights on the machine we installed the lights on the wall. This helped light up the wall with red zone lighting that was easily seen through the thick dust. The lights have been running successfully for over 3 months and all collisions have been avoided in that time. These Red Zone lights were originally designed to create a perimeter around heavy equipment like shovels, draglines and loaders but work equally well marking other hazardous areas. They are build to withstand heat, vibration, and are IP69K rated. Low current draw allows them to be wired in a series of multiple lights.

Solutions are not always complex. Having the experience in DC and AC lighting solutions across extreme environments allows APS customers to utilise a wide range of industry solutions that have been proven in rugged operating conditions.

The APS team look forward to discussing further with your team this solution and how it may also help improve your site safety and reduce collisions.